Mechanical BIM modeling has become a critical tool for modern AEC projects. It enhances project planning, design accuracy, and cross-discipline coordination, ensuring fewer errors and better outcomes.

By leveraging advanced mechanical BIM services, teams can visualize and manage mechanical systems like HVAC, plumbing, and piping within intelligent 3D environments. Let’s dive into why this is such a transformation for MEP (Mechanical, Electrical, and Plumbing) systems.

Mechanical BIM modeling is the process of creating a mechanical 3D model that represents all mechanical components of a building in a digital, data-rich format. Unlike 2D drawings, these models provide both visual representation and intelligent data, making it easier to design, analyze, and manage mechanical systems from concept through construction and into facility management. This modeling approach is an integral part of BIM modelling, providing better collaboration, fewer design conflicts, and improved project outcomes.

MEP systems are among the most complex and coordination-heavy aspects of a building. Using MEP BIM services, professionals can model and align mechanical, electrical, and plumbing systems within a single, shared digital model.

Mechanical modeling in this context helps with:

- Accurate system routing

- Early detection of design conflicts

- Improved installation precision

- Reduced construction delays

By building a coordinated mechanical 3D model, teams gain a clear picture of how systems will perform and fit within the overall structure, which is particularly important in large or high performance buildings.

One of the key benefits of MEP BIM is BIM MEP coordination. This refers to the process of aligning and integrating all building systems HVAC ducts, pipes, conduits, and more so they work together without clashes.Without proper coordination, teams often face costly on-site changes. Through BIM MEP coordination, such conflicts are resolved in the design phase using digital simulations, which improves workflow and prevents waste.

Visualizing and Managing MEP Finishes

MEP finishes refer to the visible or final components of mechanical systems, such as grilles, diffusers, and exposed pipes. These are not only functional but must also meet aesthetic and compliance standards. With mechanical BIM services, designers can model MEP finishes in detail, ensuring they align with the architectural vision. Mechanical 3D modeling enables accurate placement, sizing, and integration of these finishes, reducing costly on-site changes and ensuring quality control.

The use of 3D BIM modeling in MEP design offers several benefits:

- Real-time collaboration: All stakeholders work on a unified model.

- Enhanced visualization: Understand how systems interact before construction.

- Data-rich insights: Gain access to specs, materials, and maintenance data.

Mechanical BIM modeling also supports lifecycle planning, helping facility managers maintain and upgrade systems with confidence.

BIM modelling has become essential for delivering high-quality, on-time, and budget-friendly construction projects. It’s especially crucial for mechanical systems, where space constraints and complexity can easily lead to design and installation errors.

Whether you’re working on a commercial tower, hospital, or industrial facility, integrating Mechanical BIM services into your project ensures systems are installed as intended and function properly from day one.

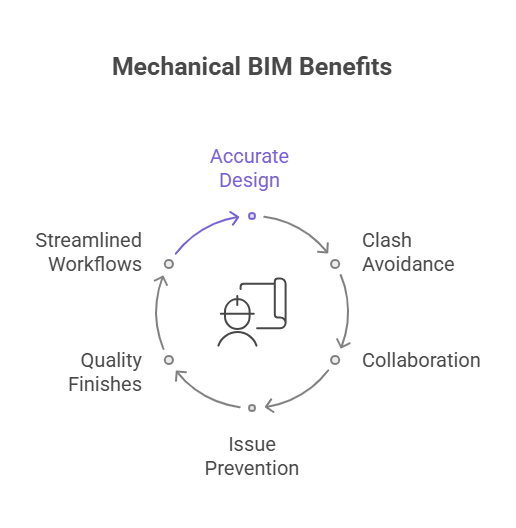

Benefits:

- Mechanical BIM modeling offers accurate, data-driven design for mechanical systems.

- Mechanical 3D models help avoid spatial clashes and optimize layouts.

- MEP BIM services improve collaboration across design and construction teams.

- BIM MEP coordination prevents costly on-site issues.

- High-quality MEP finishes are better managed with detailed mechanical modeling.

Using advanced 3D BIM modeling tools streamlines workflows and improves long-term building performance.

Incorporating mechanical modeling through advanced BIM modelling practices is no longer optional it’s essential for modern AEC success. With tools that support MEP BIM, teams can collaborate more effectively, deliver higher-quality results, and reduce costly errors.From planning to construction and through to operation, mechanical BIM services provide the accuracy, clarity, and coordination needed to build smarter, safer, and more efficient buildings.

Looking to improve your next project? Start with expert Mechanical BIM modeling with CloveTechnologies for better performance and less risk.

Mechanical BIM modeling | Electrical BIM modeling | Plumbing BIM modeling | Mechanical BIM modeling in Texas, | Fire Protection BIM modeling in Texas | Low Voltage BIM modeling in Florida, | Plumbing BIM modeling in Georgia | Mechanical BIM modeling in Illinois | Fire Protection BIM modeling in Illinois | Electrical BIM modeling California | Low Voltage BIM modeling | California BIM modeling in Georgia, | Scan to BIM | Scan to BIM in Georgia | H.V.A.C 3D Modeling in US / USA | Plumbing 3D Modeling | H.V.A.C 3D Modeling.

Discover more of our innovative blogs

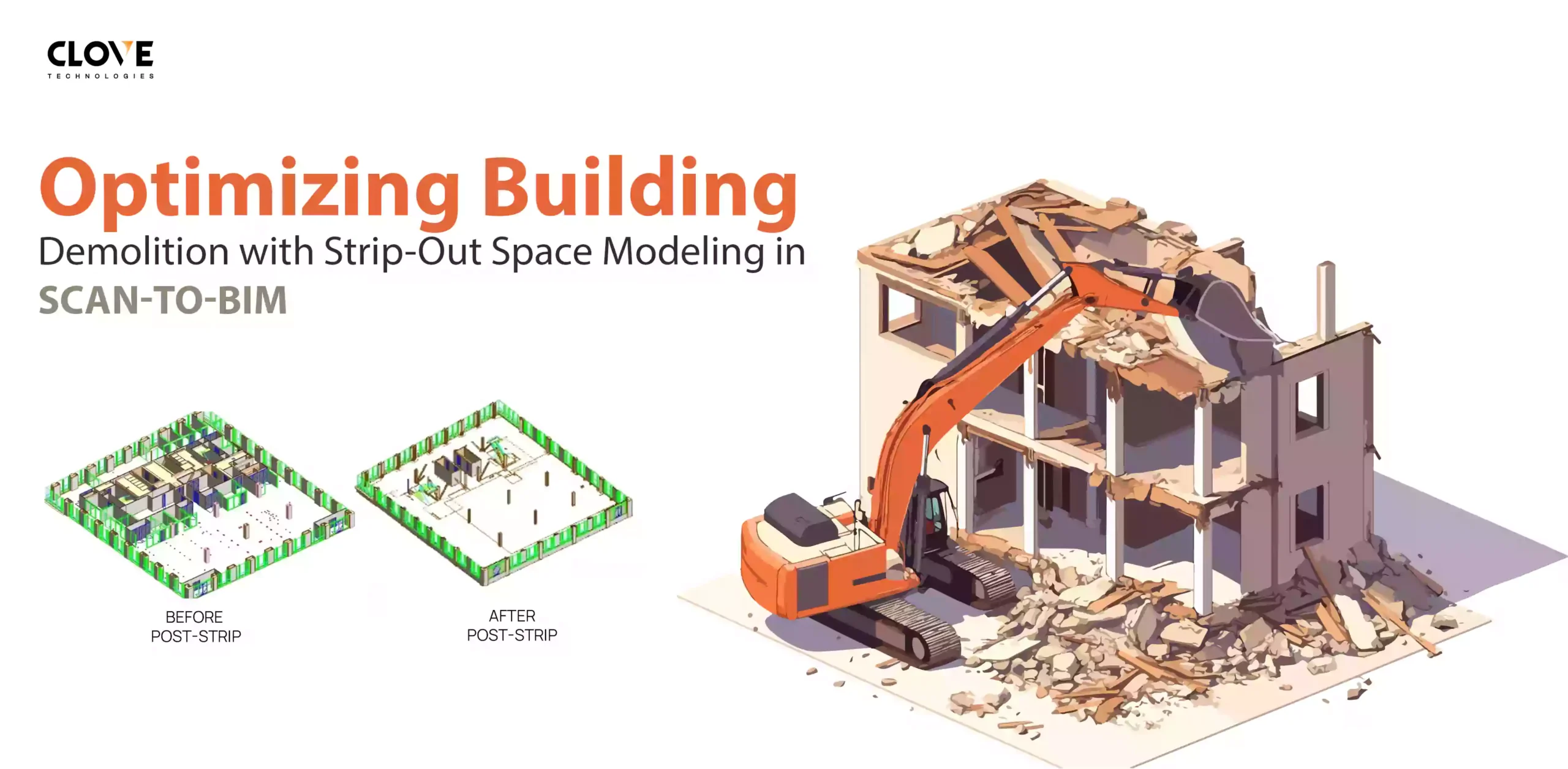

Scan-to-BIM for Demolition: A New Standard in Building Deconstruction

Clove Technologies: Setting new standards in Scan to BIM delivery

3D city modeling: The new era of gaming realism

The Best BIM Service Providers Across the USA

Let's Talk

Let’s discuss your requirements and see how our expertise can help on your next project.