Transforming manufacturing Industry : Progressing Converter Replacement through Our Digital Reality Services

Generated 2D drawings and Building Information Modeling (BIM) model to streamline the installation process for upgrading converters.

Introduction

The Manufacturing Industry aiming to streamline the installation process for upgrading converters, They assigned us the job of thoroughly examining the existing space. Utilising Digital Reality technology, our team started an initiative aimed at converter replacements. Our primary objective is to conduct a comprehensive scan of the industry and generate a 2D drawings and Building Information Modeling (BIM) model. These 2D drawings and BIM model will empower the client to compare the existing spatial layout with the specifications of the new converters, thereby facilitating installation with minimal structural alterations.

PROJECT INFORMATION:

| Client: | Facility Managers |

| SERVICE: | 3D laser Scanning, Scan to CAD, Scan to BIM |

| INDUSTRY: | Industrial |

Software Used:

Client Requirement

They required a comprehensive solution to assess the suitability of new converters with existing infrastructure. Precise measurements and detailed insights were essential to minimise renovation efforts and ensure seamless integration of the upgraded equipment.

Our Approach

Reconnaissance Survey

They required a comprehensive solution to assess the suitability of new converters with existing infrastructure. Precise measurements and detailed insights were essential to minimise renovation efforts and ensure seamless integration of the upgraded equipment.

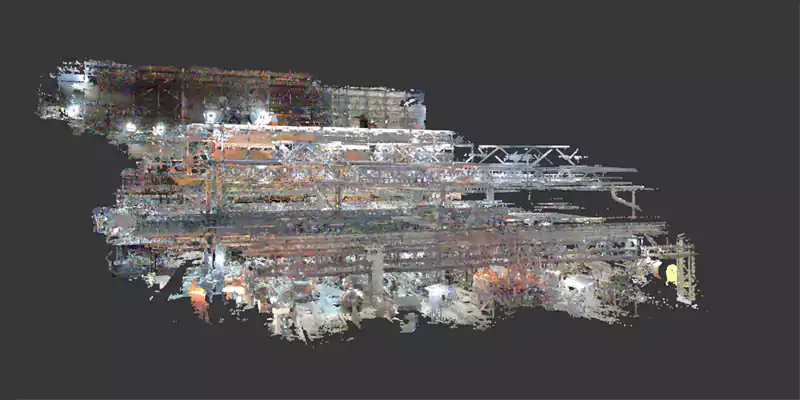

SCANNING STRATEGY AND EXECUTION

Utilising advanced mobile scanning technology, we thoroughly planned a scanning path to cover every corner of the plant, including the converters and surrounding areas. Despite facing challenges such as heat emissions from burners and confined spaces, our team formulated strategies to ensure accurate data capture. After planning, we carefully scanned the area, moving through tricky spaces with care and gathering detailed data to support detailed analysis and decision-making.

DATA PROCESSING

In the processing phase, we seamlessly combined multiple data sets from scanning different sections of the industry into one model. The collected data underwent comprehensive processing to eliminate noise and ensure accuracy. We refined the data to create a precise digital representation of the Industry layout.

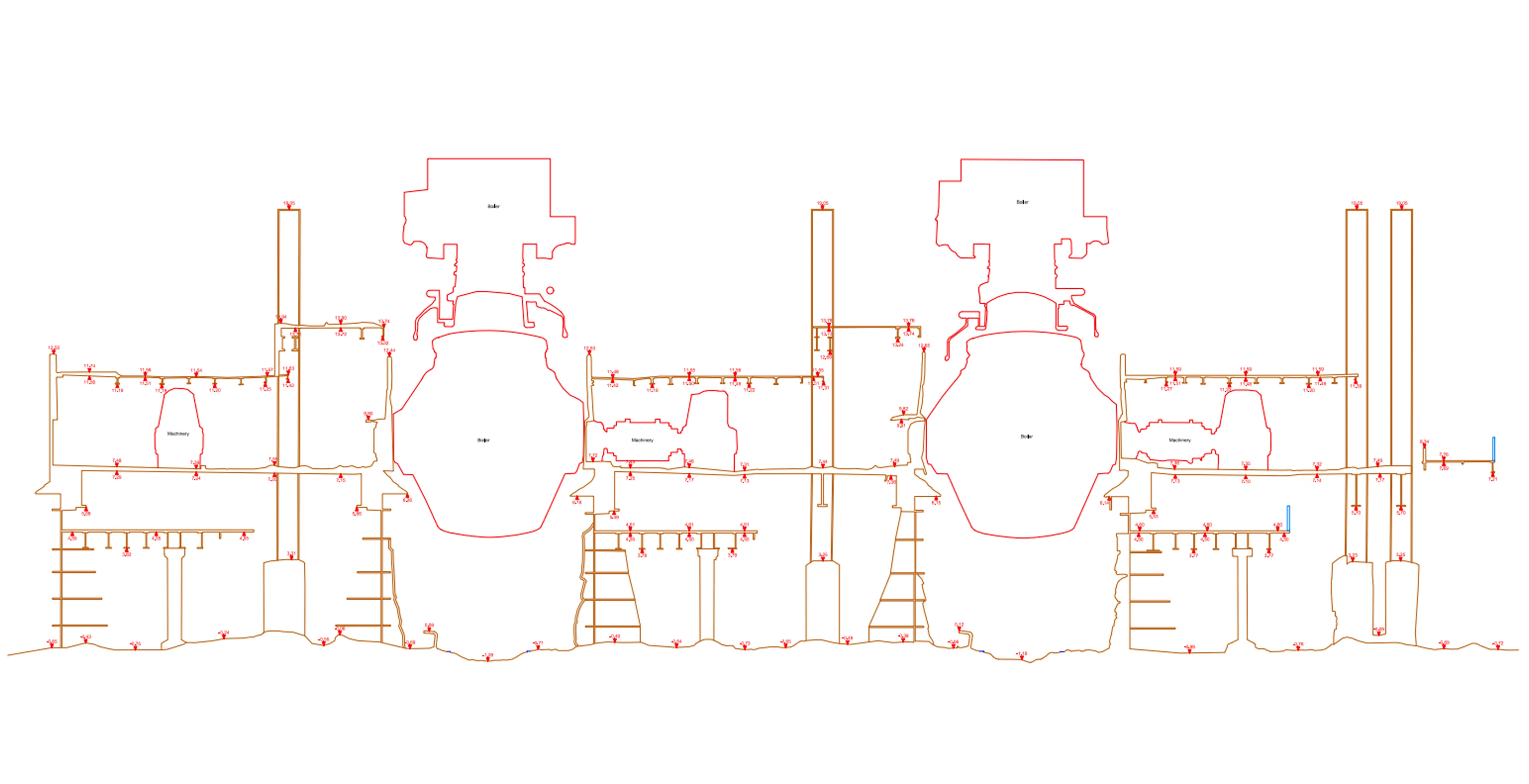

2D DRAWING GENERATION

We provided 2D drawings of the converters using point cloud data obtained from the scanning process. These drawings included floor plans, ceiling plans and sections, offering further detailed information about the existing area along with dimensions. This additional deliverable enhanced the client's understanding of the spatial layout, aiding in planning and decision-making processes.

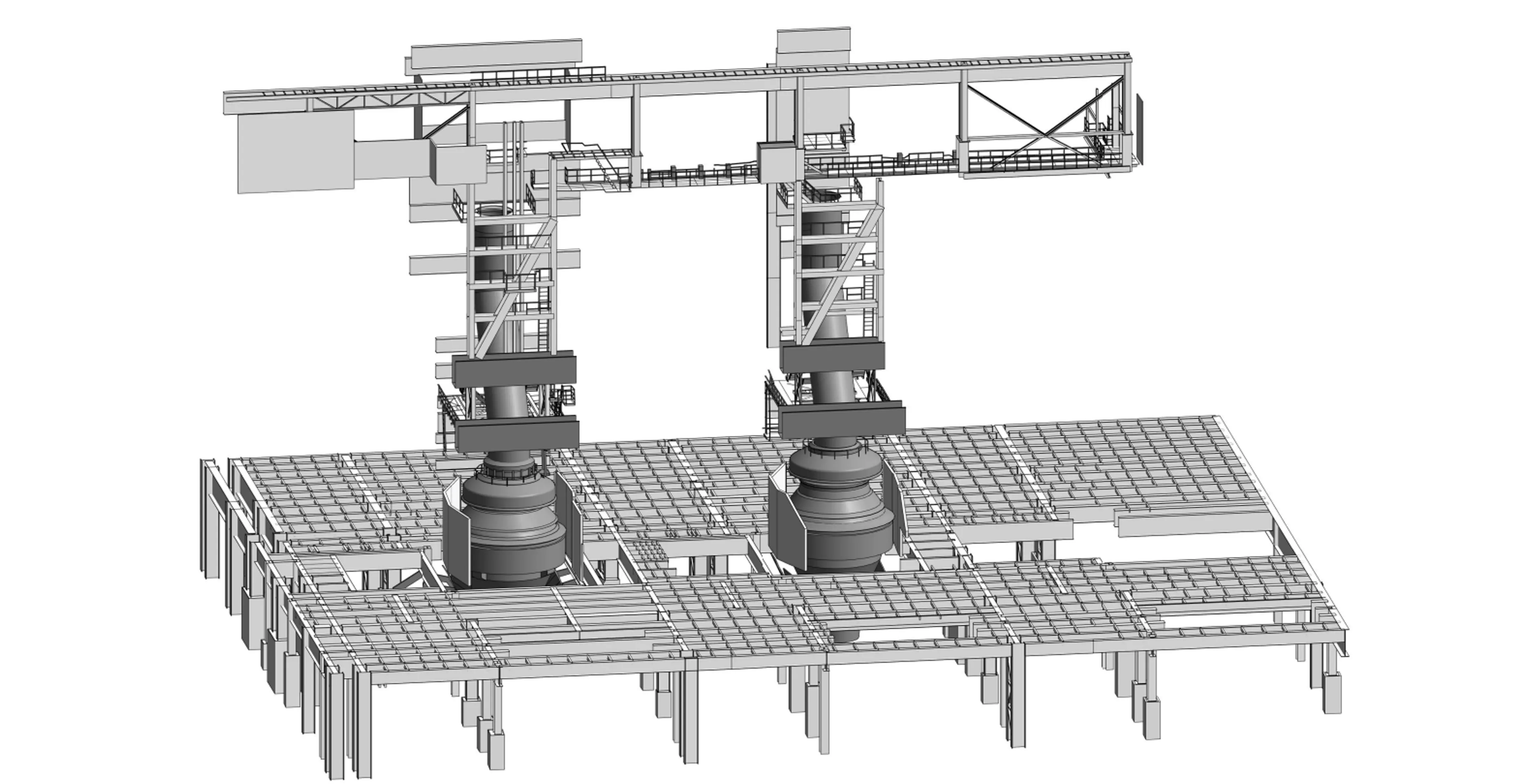

BIM MODELING

Based on the processed data, we developed a detailed Building Information Modeling (BIM) model of the industry. The BIM model included precise measurements of the existing structures and spaces, allowing the client to accurately assess the compatibility of new converters with the available area. This comprehensive model provided the client with a virtual representation of the existing layout, facilitating informed decision-making regarding converter replacement.

CHALLENGES FACED

HEAT EMISSIONS

Burners emitted significant heat, requiring careful planning to mitigate its impact on scanning equipment and the surveyor.

CONFINED SPACES

Narrow staircases and restricted access areas posed challenges for data capture.

GAS RELEASES

Occasional nitrogen gas releases necessitated safety protocols and temporary halts in scanning activities.

DUST DISRUPTION

The presence of a large amount of dust in some areas affecting data accuracy. We adjusted our approach to maintain precision in our measurements.

OUTPUTS PROVIDED

OUTCOME AND BENEFITS

INFORMED DECISION-MAKING

Detailed BIM model and 2D drawings empowered precise planning, ensuring compatibility of new converters with existing infrastructure.

COST AND TIME SAVINGS

Eliminated unnecessary renovations, saving costs and minimising downtime during converter replacement.

STREAMLINED PROJECT EXECUTION

Facilitated smooth project coordination and timely decision-making with interactive data visualisation.

CONCLUSION

Through our innovative Digital Reality service, we empowered the manufacturing industry with the tools and information needed to streamline their converter replacement process. Despite facing various challenges on-site, our team successfully delivered accurate data and actionable insights, demonstrating the effectiveness and value of our solution in industrial settings.

If you intend to act, we are ready to help!

Got a project in mind?

Let's discuss your project, Share your project details with us and our team will be in touch quickly to assist you every step of the way.

What is the nature of your business?

What is the nature of your business?

What services are you interested in?