This case study will delve into the step-by-step process of Lift Shaft Validation, highlighting its benefits and demonstrating how it enables contractors to make informed decisions when installing lifts.

Introduction

Lift Shaft Validation is a service designed to streamline the process of lift shaft alignment validation. By combining surveying techniques with CAD files provided by clients, This offers an accurate and detailed report on the variation between the design and as-built lift shafts. This case study will delve into the step-by-step process of Lift Shaft Validation, highlighting its benefits and demonstrating how it enables contractors to make informed decisions when installing lifts.

PROJECT INFORMATION:

| Client: | Contractor |

| SERVICE: | Structural, 3D Lasar Scanning |

| INDUSTRY: | Commercial |

Software Used:

Our Approach

Client Engagement

The client provided the CAD drawings of the lift shafts, which served as a reference for the subsequent surveying work. This collaboration ensured that the design intent is clearly understood and any specific requirements or constraints were taken into account.

Surveying the Lift Shaft Area

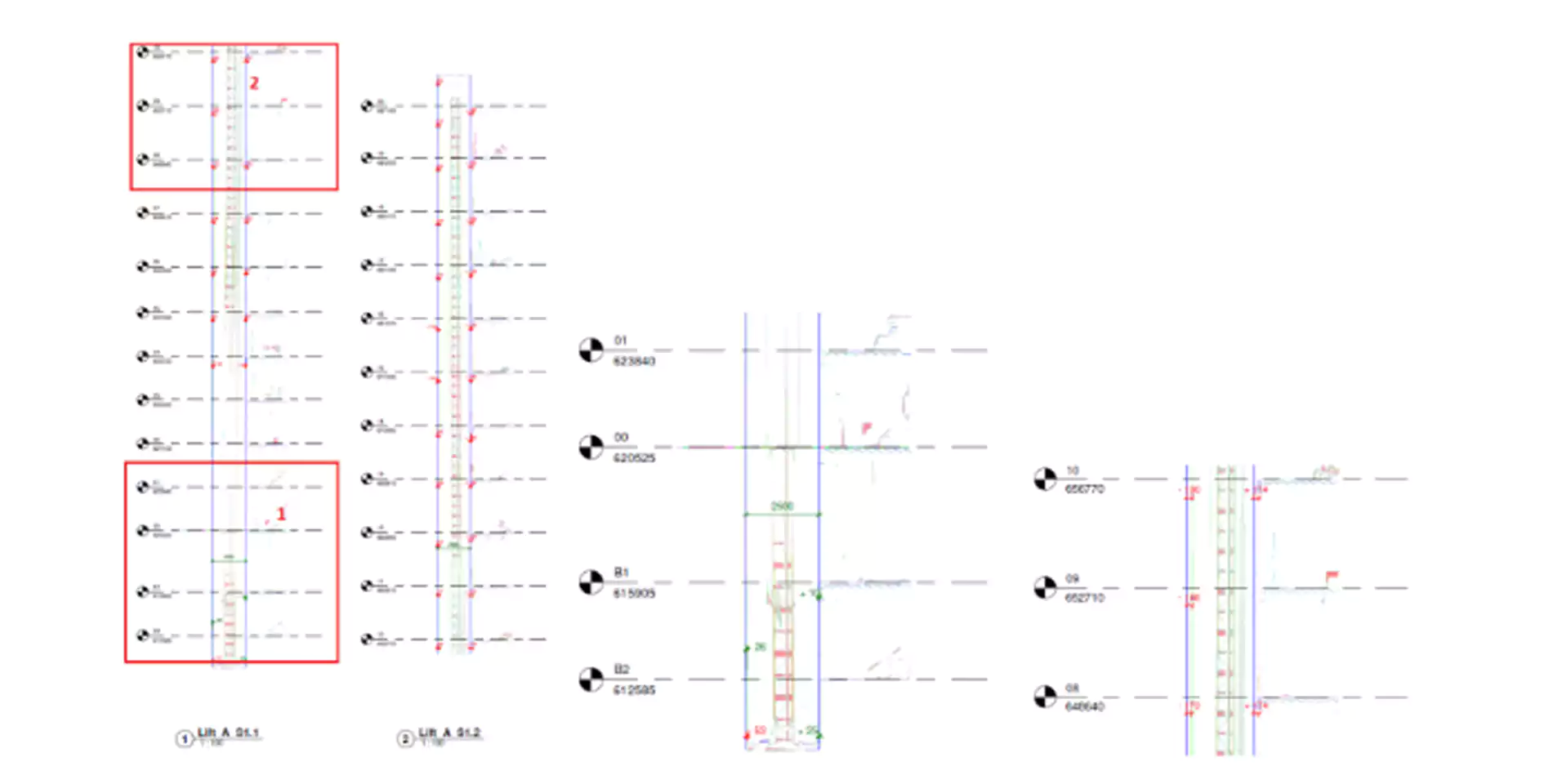

Once the CAD drawings were obtained, the team carried out a comprehensive survey of the lift shaft area. Utilising advanced surveying equipment, such as laser scanners, they captured highly accurate measurements of the physical space. This process generates a detailed point cloud, representing the precise dimensions and contours of the shaft area. The output of the scanned data shown in the image below.

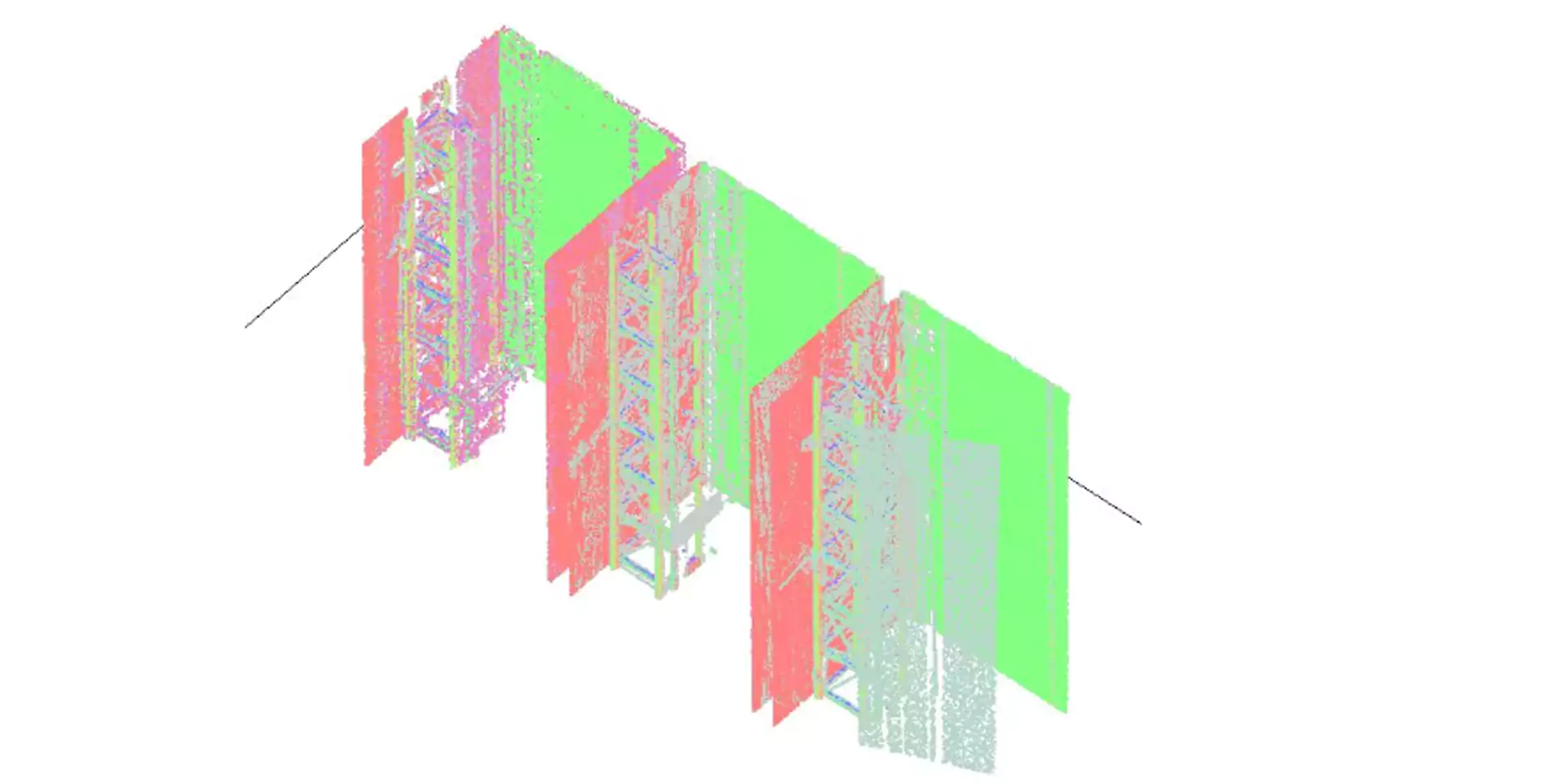

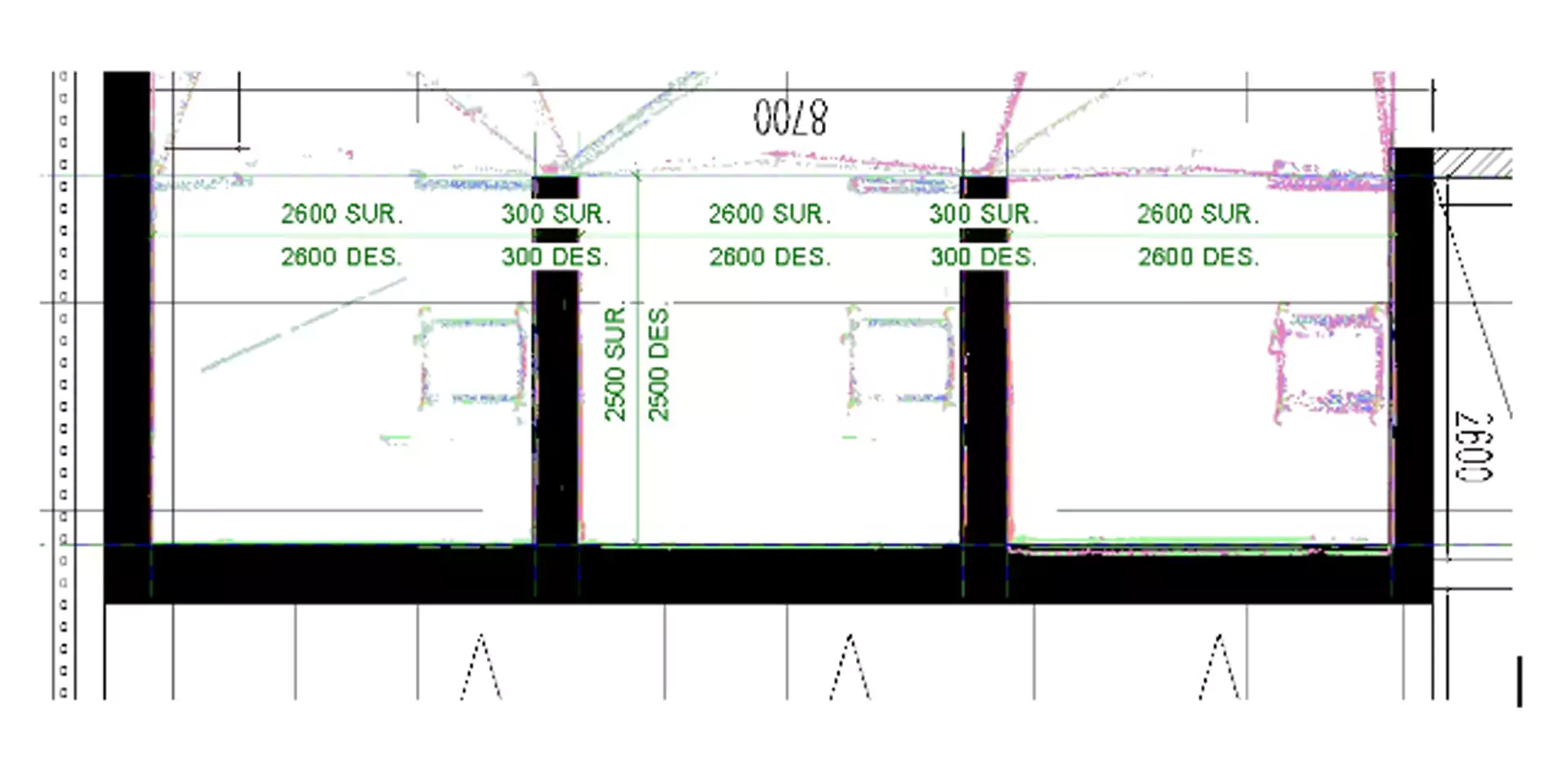

Aligning Design (CAD Drawing) and Point Cloud

Next, the CAD drawing provided by the client was overlaid onto the point cloud generated from the surveying data. This alignment allows for a direct comparison between the intended design and the as-built environment. By merging the two datasets, the deviations and variations became apparent, enabling a comprehensive analysis of the lift shafts. In below images you can see the 2D and 3D view of aligning design with as-built point cloud.

Vertical Deviation Analysis

Using the aligned CAD drawing and point cloud, the team calculated the vertical deviation of each floor within the lift shaft. The ground floor served as the reference point and the measurements of subsequent floors were compared against it. Positive deviations indicate an increase in measurement, while negative deviations signify a decrease. These deviations were provided in millimeters, offering a high level of precision.

Variance of Plan to Plan of Lifts

In addition to the vertical deviation analysis, this process also highlights the variance between the planned position of lifts on each floor and their as-built locations. This information is crucial for contractors, as it ensures that the lifts are accurately placed, adhering to the design intent. By identifying any discrepancies, contractors can make informed decisions and adjustments during the installation process.

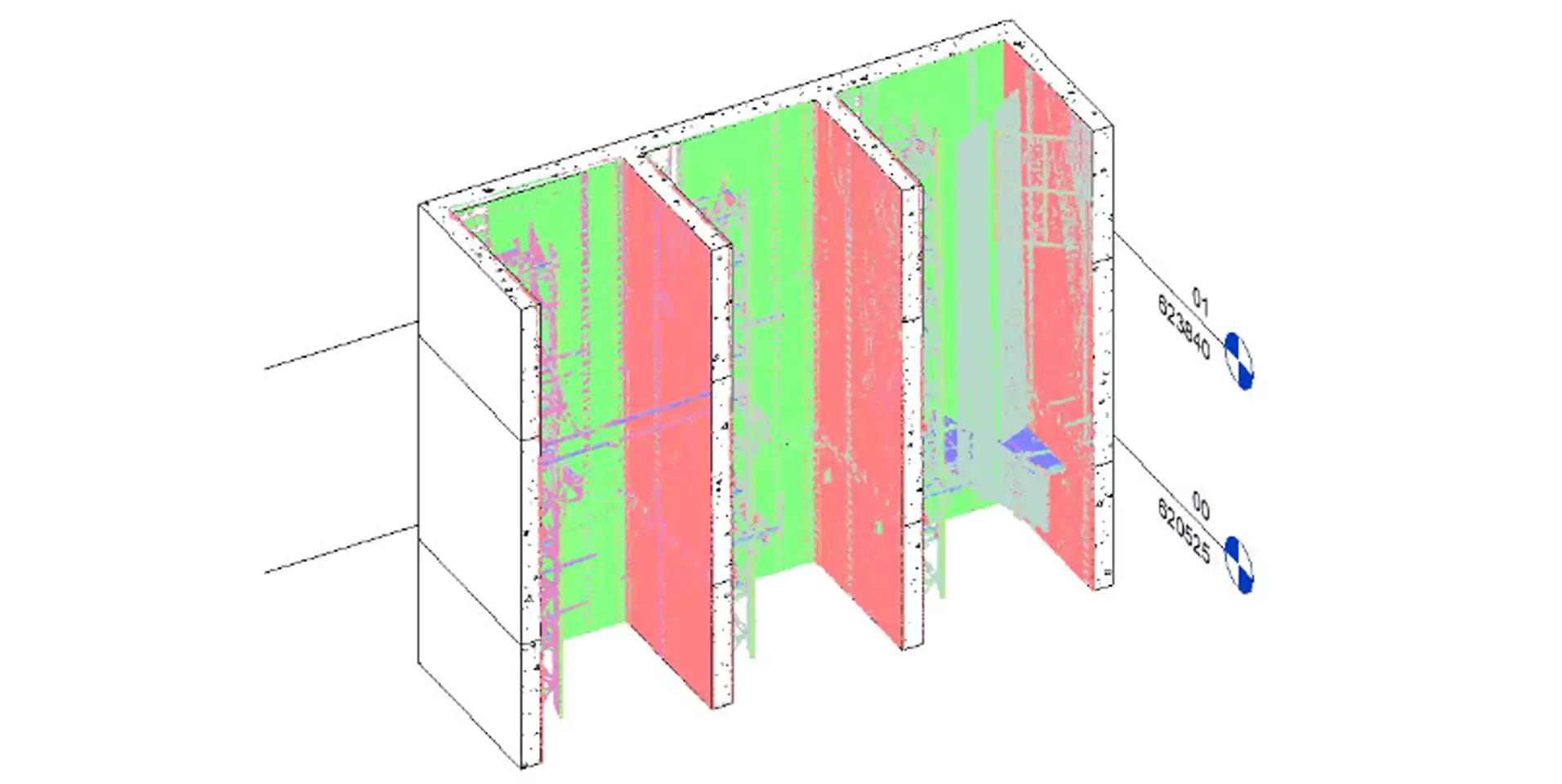

Report Generation:

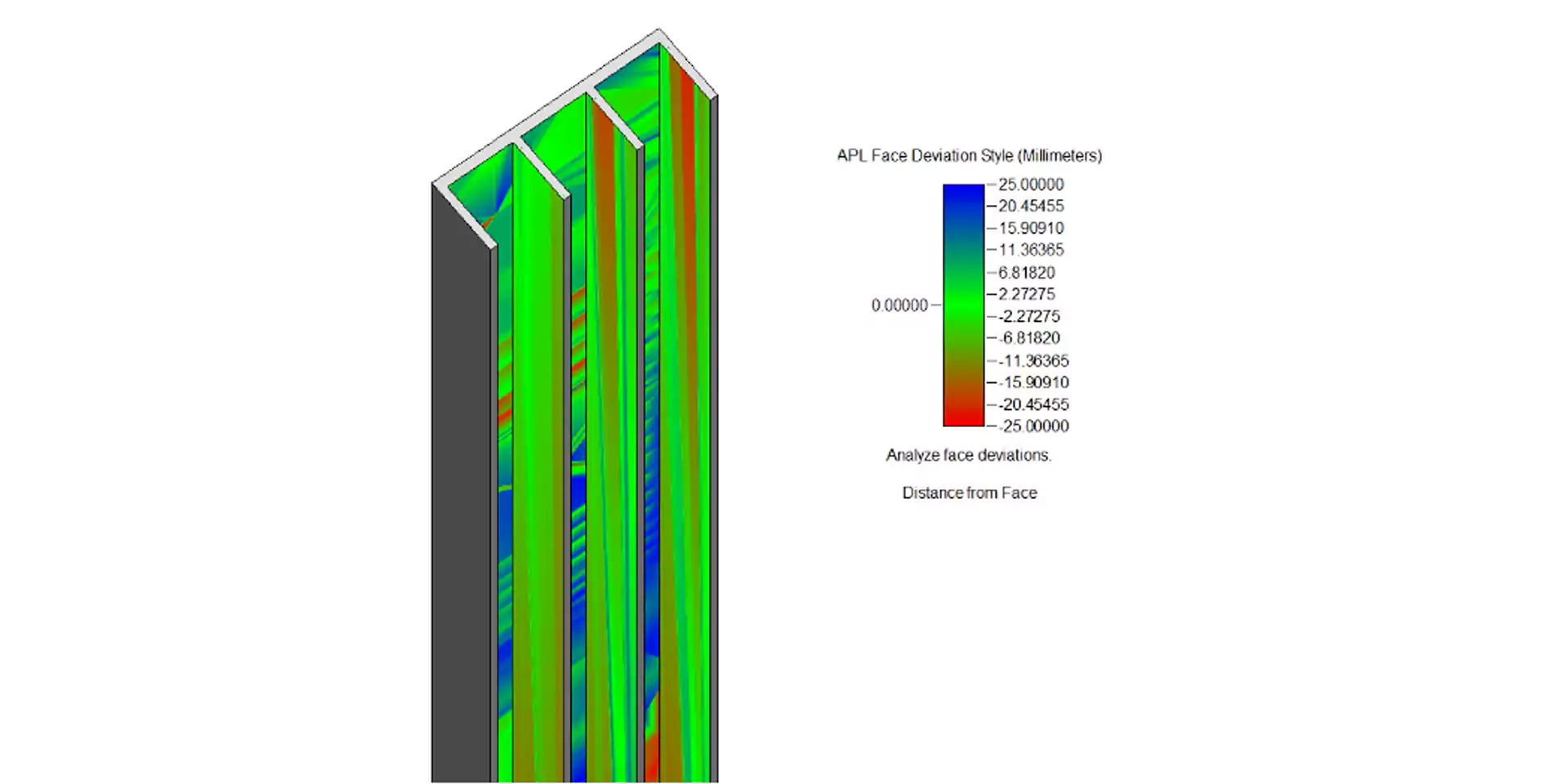

Based on the analysis performed, the team generated a comprehensive report detailing the variations between the design and as-built lift shafts. The report includes visual representations, such as annotated CAD drawings and 3D models, providing a clear understanding of the deviations. These detailed insights empower contractors to rectify any misalignments and ensure the lift installation adheres to the original design. We are showing the deviation of lift shafts in a heatmap.

The Consequences of not validating Lift Shaft Alignment

Contractors who choose not to use lift shaft alignment validation service, may face various conflicts. Without precise measurements, inaccuracies in lift shafts can occur, leading to deviations from the intended design. Misinterpreting complex CAD drawings becomes a challenge, potentially resulting in confusion and mistakes during construction. Costly rework is likely if misalignments are discovered only after lift installation begins. Safety concerns arise from improperly aligned shafts, as risks like uneven landing levels and door misalignment may occur. Communication gaps and coordination issues can arise among stakeholders due to the lack of a standardised validation process. Reduced efficiency and productivity result from manually analysing drawings and conducting measurements, leading to delays and increased costs.

OUTPUTS PROVIDED

CONCLUSION

Lift Shaft Validation offers an innovative solution, providing contractors with accurate measurements and analysis. By leveraging CAD files and surveying data, this service enables the identification of vertical deviations and variances between planned and as-built lift positions. This comprehensive report equips contractors with the necessary information to make informed decisions during the installation process, ultimately ensuring the smooth operation and functionality of lifts within buildings. Through this, contractors can confidently achieve precise and accurate lift shaft alignments, resulting in improved safety and customer satisfaction.

If you intend to act, we are ready to help!

Got a project in mind?

Let's discuss your project, Share your project details with us and our team will be in touch quickly to assist you every step of the way.

What is the nature of your business?

What is the nature of your business?

What services are you interested in?