Clove Technologies' advanced structural modeling and detailing services facilitated the precise design and development of a complex commercial building, ensuring structural integrity, enhancing construction efficiency, and supporting seamless project execution

Initial Insights

This case study focuses on a commercial building project undertaken in the structural modeling domain. The primary objective was to create a highly detailed and precise 3D structural model, encompassing every aspect of the building’s framework, from steel reinforcements to complex connections. Structural modeling for commercial buildings poses unique challenges, particularly in terms of load-bearing elements, complex geometry, and rigid design standards. This project provided an excellent opportunity to showcase our expertise in handling intricate structural detailing while adhering to the highest accuracy and safety standards.

.webp)

PROJECT INFORMATION:

| Client: | Architects |

| SERVICE: | Scan to BIM |

| INDUSTRY: | Commercial |

Software Used:

Key Project Highlights

.webp)

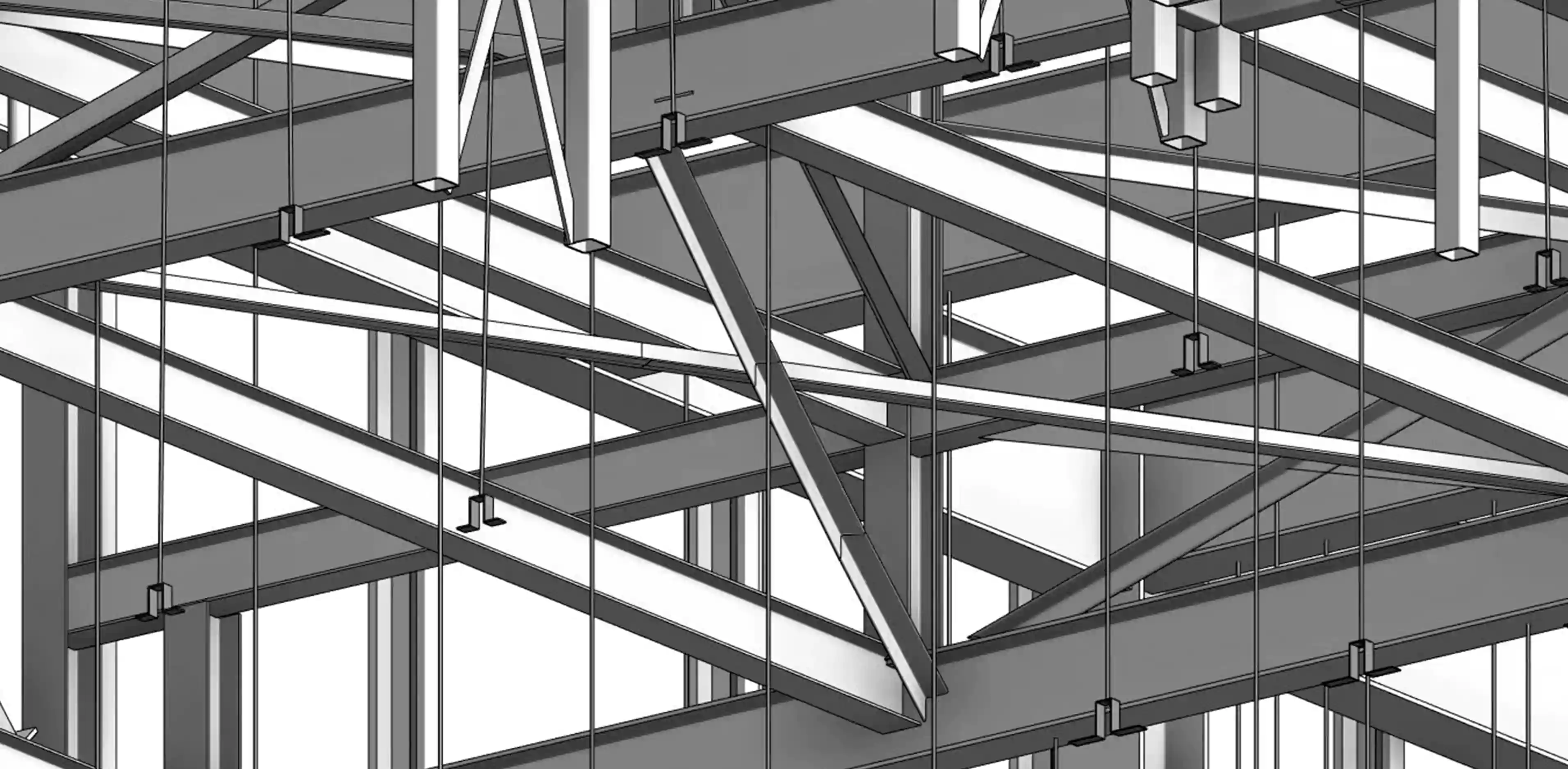

Project Complexity

Structural modeling for commercial buildings presents numerous challenges due to the intricate interplay of various load-bearing components. This project was particularly demanding because:

.webp)

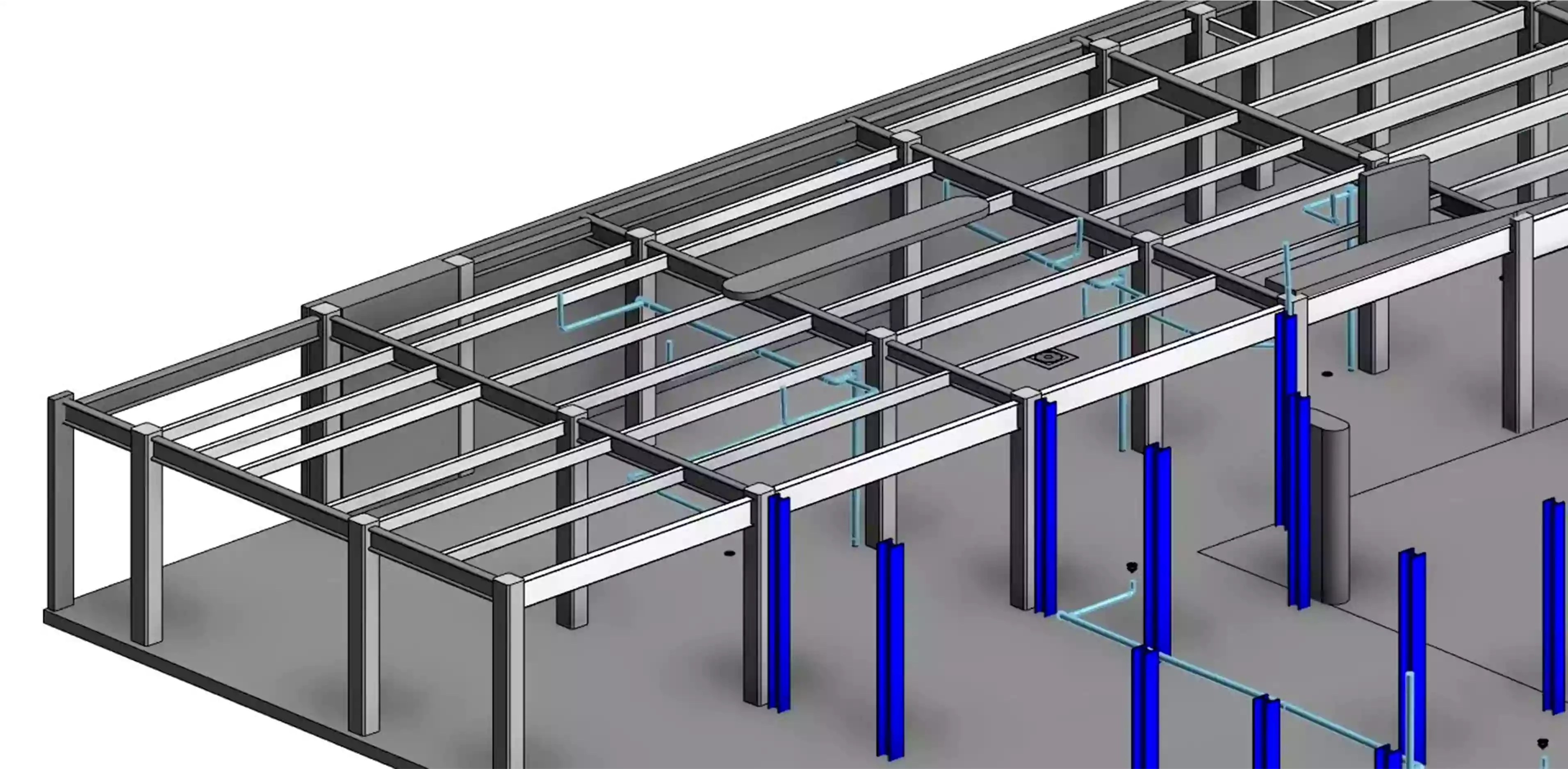

Methodology

To address these complexities, we adopted a structured approach:

.webp)

Challenges and Solutions

Challenges

Solutions:

Advantages

Conclusion

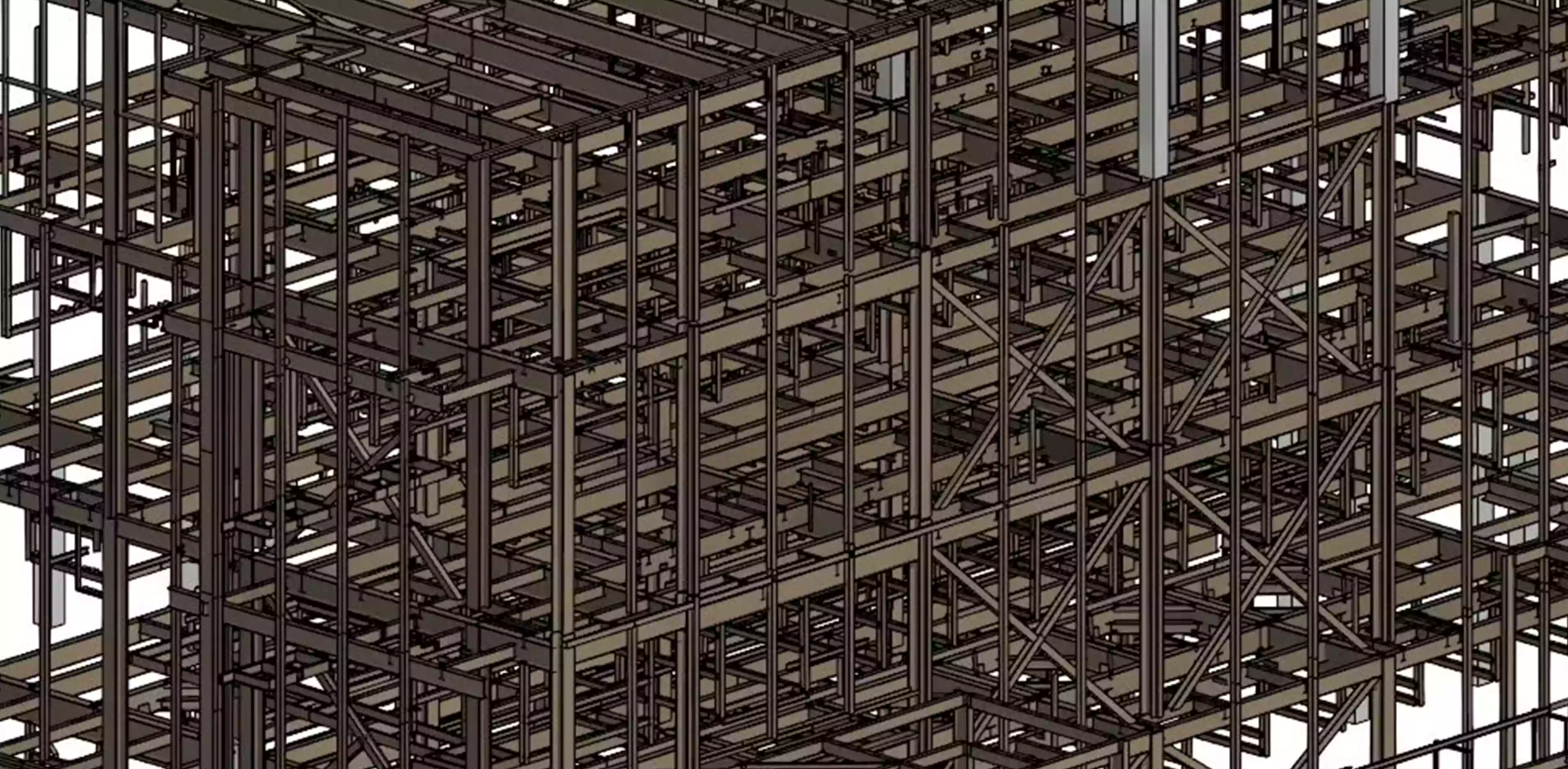

This project demonstrated our ability to handle complex structural modeling assignments for commercial buildings. By addressing unique challenges such as intricate connection detailing, irregular geometries, and data overload, we delivered a highly detailed and precise 3D model that served as a valuable asset throughout the construction and fabrication process. Our structured approach, combined with advanced BIM and structural analysis tools, enabled us to meet the project’s high standards while ensuring efficiency and accuracy. The insights and methodologies developed here form a strong foundation for future structural modeling endeavors, particularly in high-rise and large-scale commercial projects.

If you intend to act, we are ready to help!

Got a project in mind?

Let's discuss your project, Share your project details with us and our team will be in touch quickly to assist you every step of the way.

What is the nature of your business?

What is the nature of your business?

What services are you interested in?