Rebar Plan & details were developed from the Input drawings that were provided and delivered within the specified time frame.

SUMMARY OF THE PROJECT

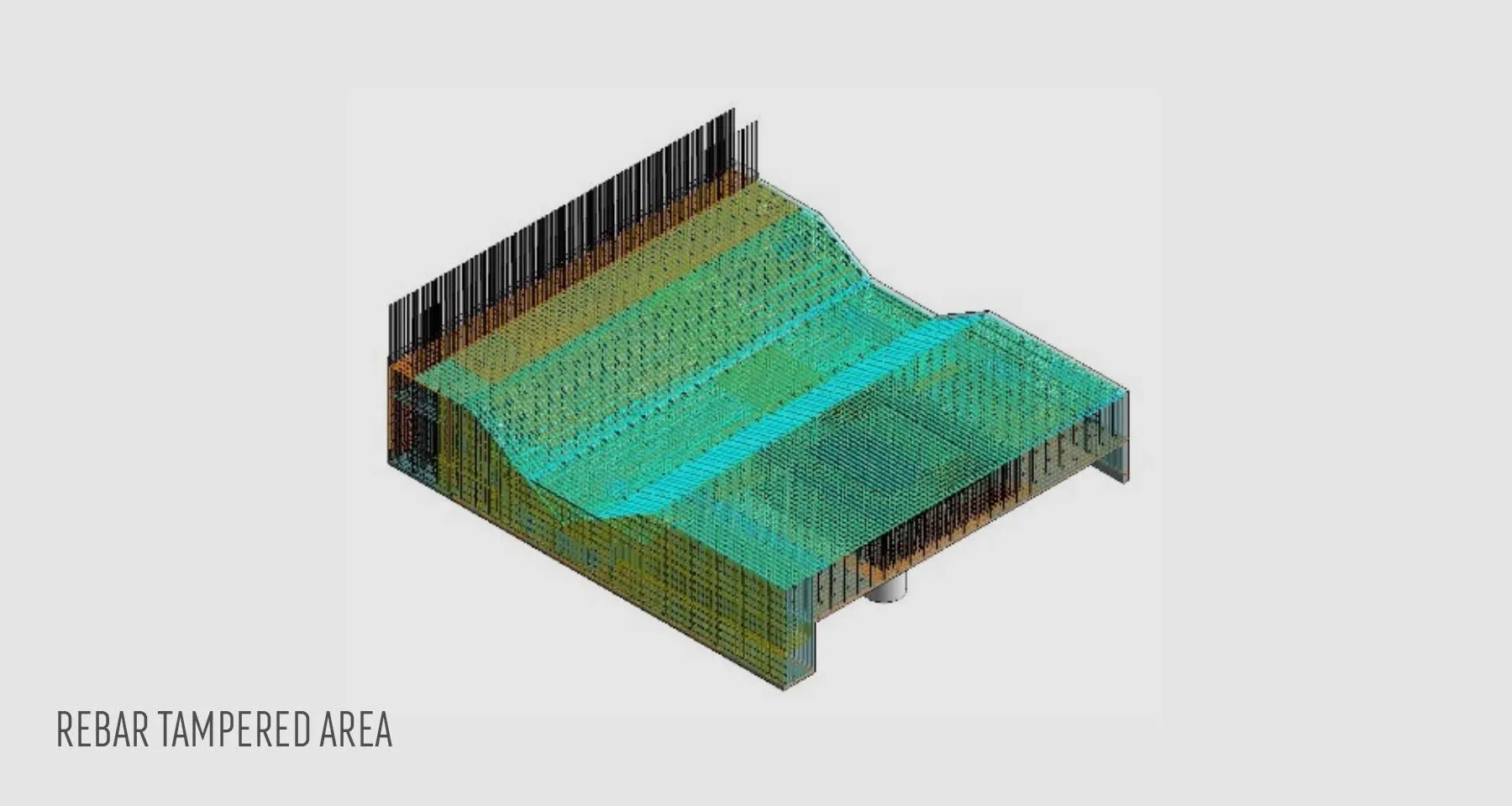

Clove Technologies beat international competition to bag a series of major projects involving Bar Bending Schedule (BBS) services. We had provided technical expertise in two infrastructure and two commercial facilities that are based offshore. Steel structure and engineering service provider firm from Australia collaborated with Clove Technologies to assist them develop detailed rebar drawings,Bar Bending Schedule (BBS) and Tekla models for a commercial building and infrastructural type of development project. Rebar Plan & details were developed from the Input drawings that were provided and delivered within the specified time frame.

PROJECT INFORMATION:

| Client: | Fabricators |

| SERVICE: | Structural, BIM Modeling, Architectural |

| INDUSTRY: | Educational, Rail |

Software Used:

WHAT WAS DONE?

The scope entailed as mentioned below:

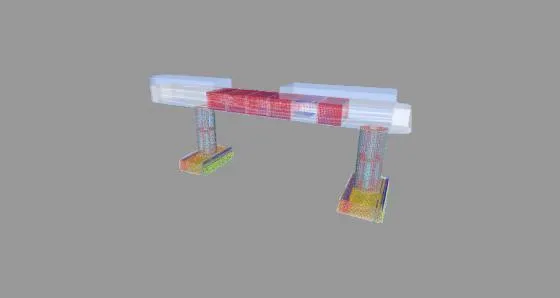

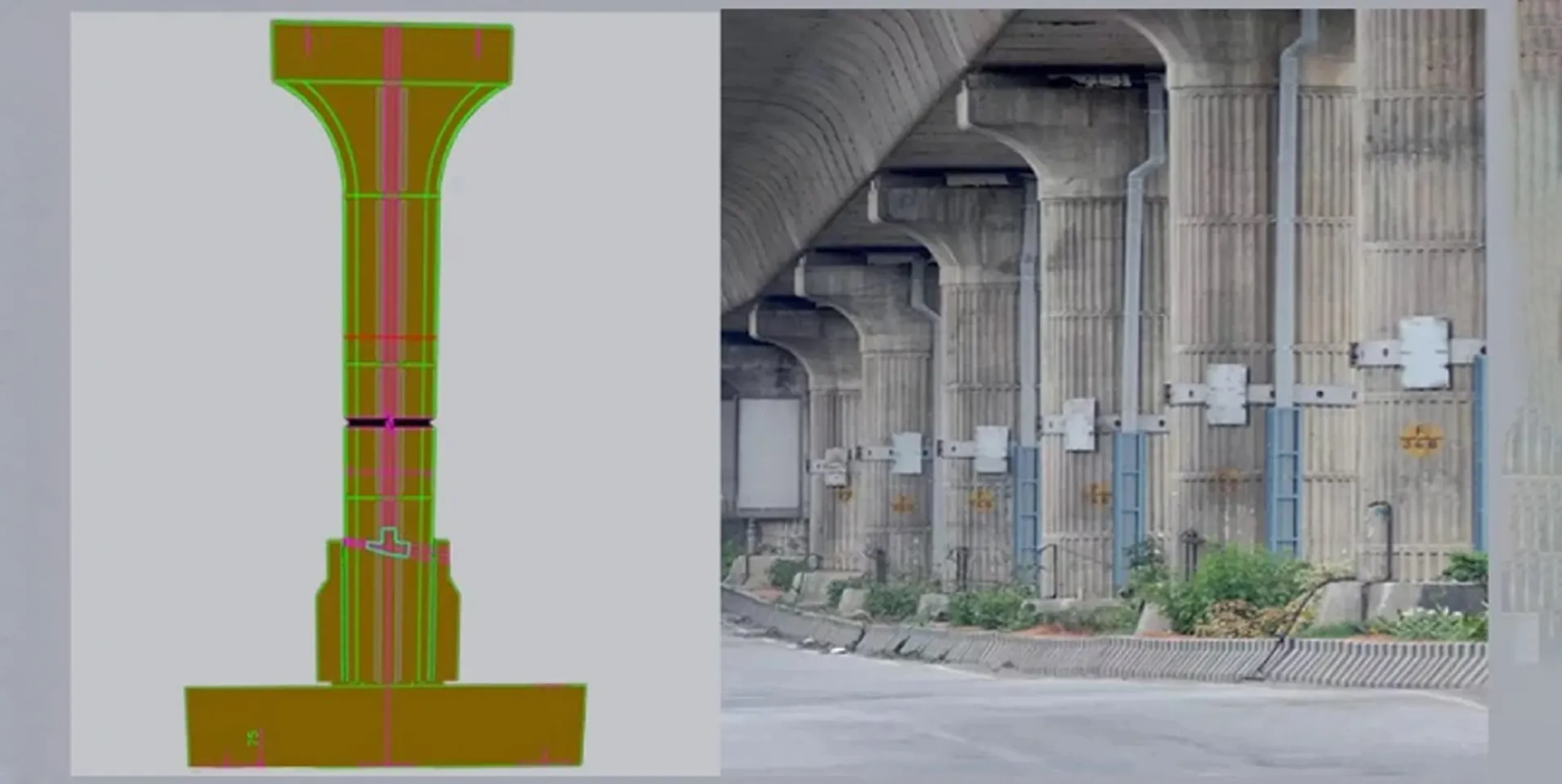

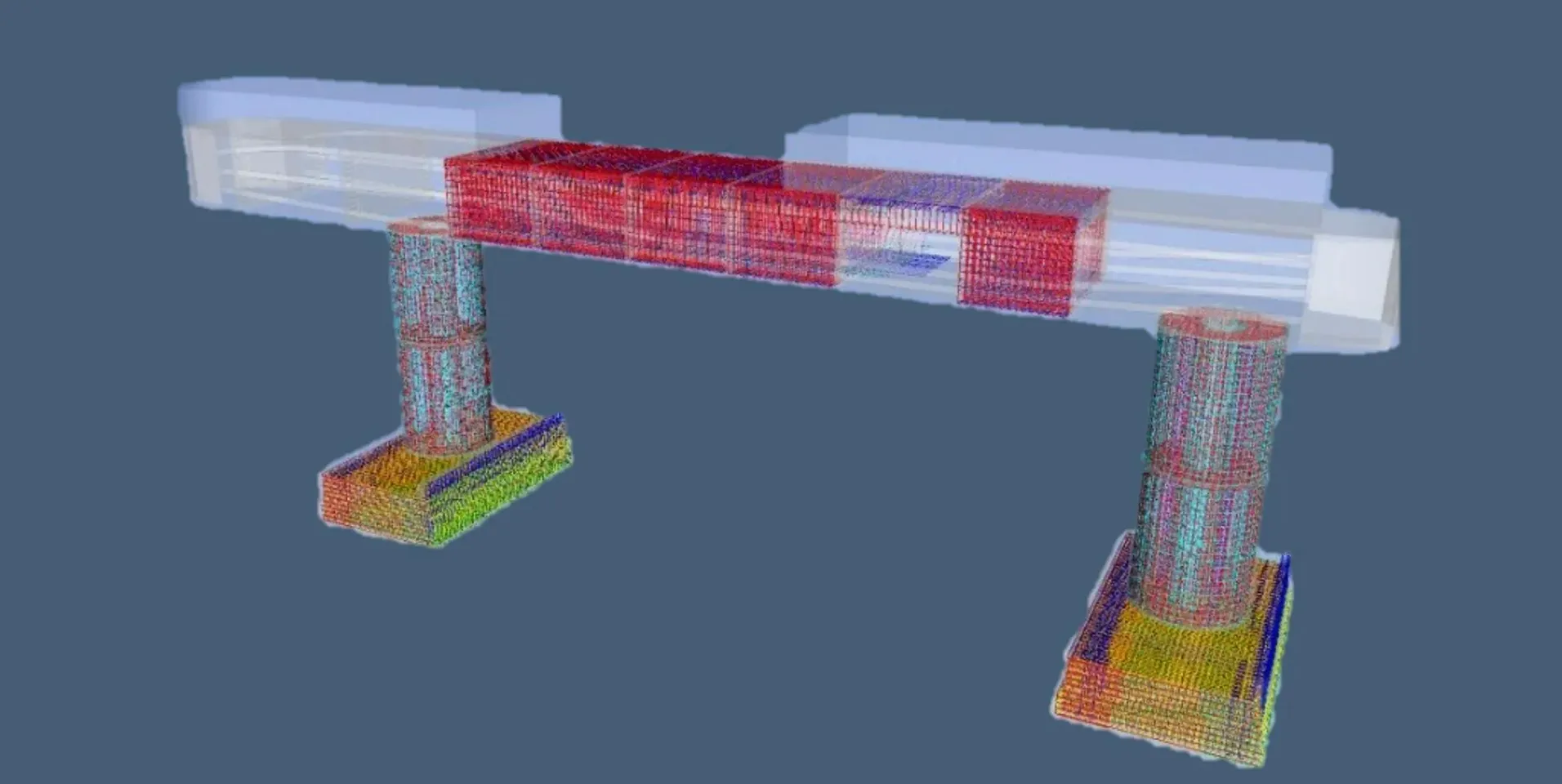

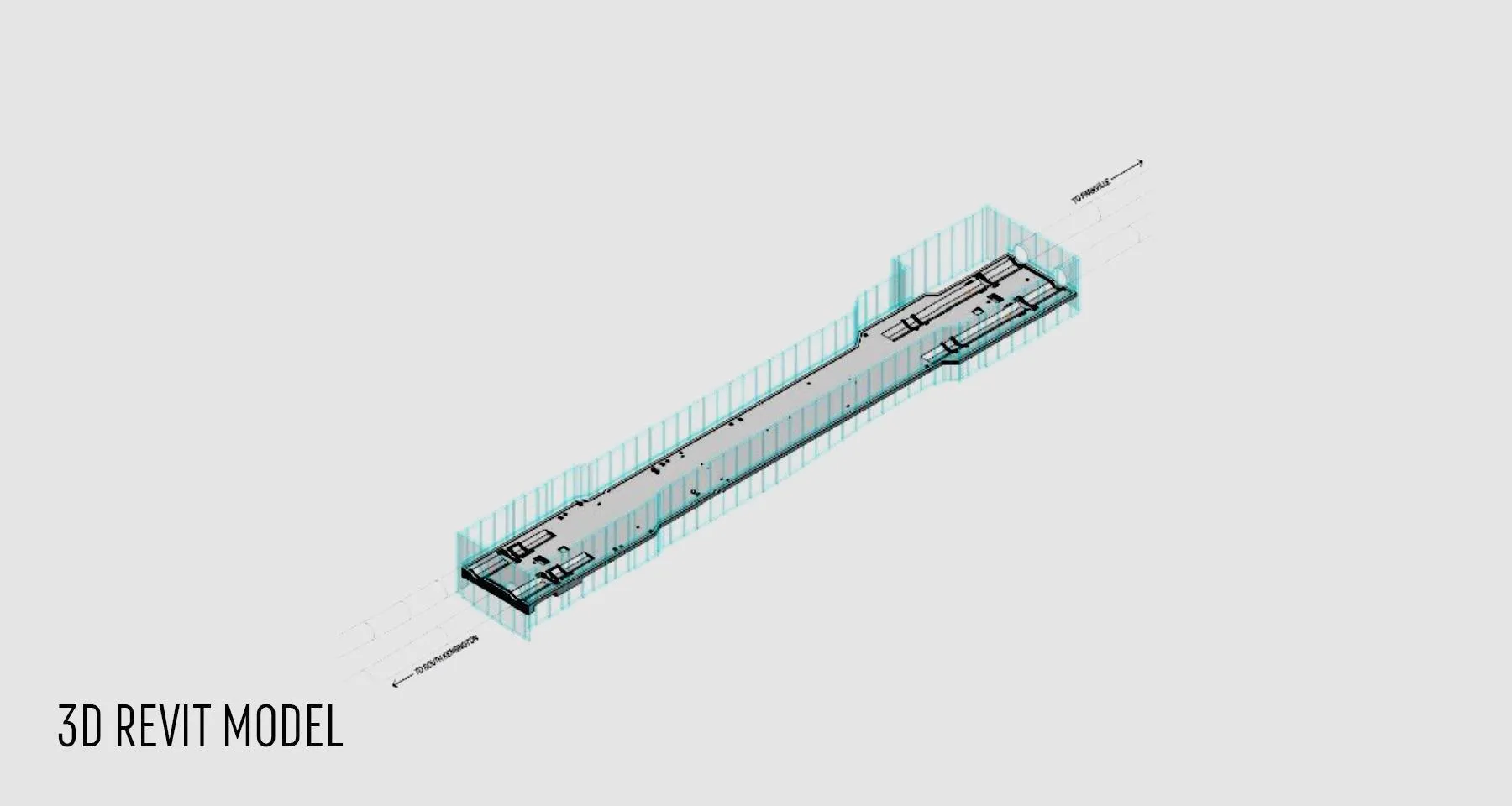

Clove Technologies Pvt Ltd. has delivered 3D Model, 2D drawings for Steel reinforcement andBar Bending Schedule (BBS)s for the below series of projects:

| Educational Institute: | 2D shop drawings for steel reinforcement – ManualBar Bending Schedule (BBS) |

| Railway bridge: | ManualBar Bending Schedule (BBS) , CAD – RC |

| Gate tunnel & Metro: | 3D revit model and automaticBar Bending Schedule (BBS) (CAD – RC) |

CHALLENGES

The scope entailed as mentioned below:

Key take-away

WHAT WERE THE KEY OUTCOMES?

Bar bending schedule:

BIM: