Al Rayyan Stadium Case Study

Summary of Project

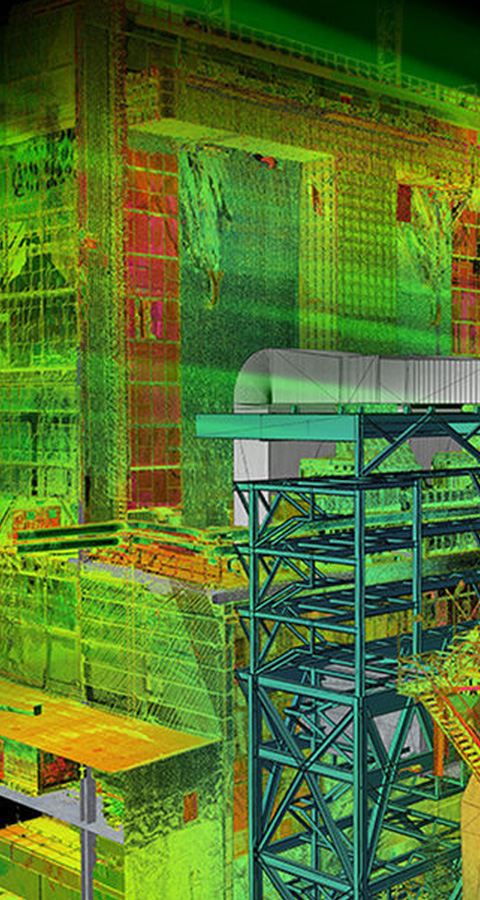

Clove Technologies Pvt. Ltd. is working on “High Precision Interior Fit Outs Modelling of Al Rayyan Stadium” Project using BIM technology.

The Al Rayyan Stadium’s spectacular façade mirrors the Qatari Culture

with sand dune-shaped structures surrounding the venue. It has a proposed seating capacity of 21,282 and will be expanded to 44,740 using modular elements to form an upper tier. Every part of the stadium district has

been designed with sustainability in mind. Half of the stadium’s seats will be removed and given to football development projects abroad.

Capacity of the Stadium: 40, 000 Seats (Net) 45, 000 Seats

Stadium Floor Area: 1,03,665 Sqm Max Ht. 46.4m (34.74m)

North: Project North

Energy Centre: 8,177 Sqm

Substations: 725 Sqm

Scope of Work

The Project commenced with complete digitization of the primary design documents the customer had provided, followed by building 3D designs while keeping an eye on clashes and design conflicts.

Model Updations, Shop Drawing & BOQ Extraction of Interior Fit Out Package for the following areas spanning 7 levels (includes 2 Basements)

- GA Concourse

- VVIP, VIP, Prayer Rooms

- Sky Box

- FIFA Related Work Rooms

- Toilets

- Concession Areas

- BOH Areas

Total Number of Sheets for 7 Levels: 1475 (Approx.) A1 & A2 Size Sheets

Zones: 40

Total Site Area: 548,971 Sqm

Landscape Area: 251,100 Sqm

Total Parking: 3408 Nos.

Project Details

Project Title: Al Rayyan Stadium

Client: Classical Palace (Sub-contractor to ABLT for Interior Fit out Package.)

Type of Project: Model Updation, Shop Drawing & BOQ Extraction of Interior Fit Out Package for the following areas spanning 7 levels (includes 2 Basements)

Project Duration: Four Months (Approx.) depending on the revisions in Specifications and details.

What were the key Outcomes?

- By using shared model methodology, we were able to meet tight deadline of 4 months for a delivery schedule of 1475 drawings.

- Accuracy, quality, coordination & collaboration was accomplished due to digital information available to all team members at real time by adopting CDE model.

- Detailed clash detection reports way before the actual construction helped the stakeholders save a great deal of time and money. Creating case simulations gave us power to show planned, estimated and actual construction sequence variations as well as its consequences

- Using BIM methodology, we were able to establish improved collaboration between teams especially while creating BoQ’s and schedules, which was very important while constructing such complex purpose-built projects.

- Design documentation was automatically generated via schedules & quantification reports.

- Created vast array of libraries for various components which were accessible to all team members.

- Any change in architectural model/ structural/MEP model design change or revision was automatically updated in Interior Design model.

- By creating an accurate model, we found massive improvement on site, especially concerning the installation and construction sequence, leading to the need of lesser manpower and lesser time spent on site.

Challenges

Short Deadlines and response Time: In order to compete in this current world, one must complete projects in very tight deadline. For this Project we had 4 months deadline for a delivery schedule of 1475 drawings.

Generating Effective and accurate quantification Reports.

This stadium has sand dune-shaped structures which have curvilinear and angled walls. Modelling of such structures are a complex and time-consuming task. A lot of clashes were detected for MEP elements while

designing these sections.