Facade Case Study

SUMMARY OF THE PROJECT

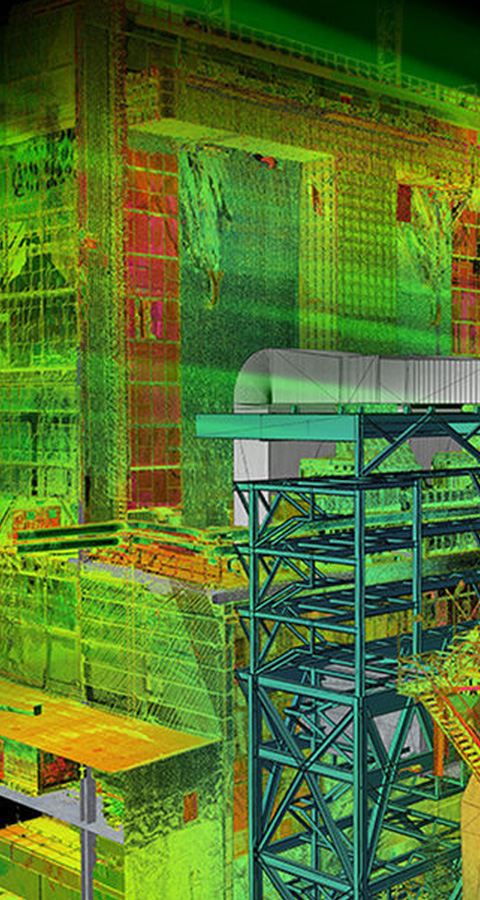

Clove Technologies offered perforated metal modelling of elements in BIM platform that allowed architects, designers and contractors to visualize the true nature of perforated metal components in a virtual environment, permitting them to see how objects

and scenery appear through the perforated material and how light flows through the components.

The whole team was always on the same page to execute the exact structure drawings intended to everyone (client, Architectural engineers, managers, etc).

WHAT WAS DONE?

The Scope entailed as mentioned below:

Clove Technologies Pvt Ltd. has completed modelling and delivering fabrication drawings for Perforated Screens on Canopy. The Scope required 3D modeling & CAD Shop drawings/Fabrication drawings (75) for Roof Sheet Perforated Screens on Canopy

Specifics that the client required:

Sheet Model Connection Details

After model Completion Shop Drawings

PROJECT INFORMATION

Client A Specialized company in designing-Façade projects.

Location Sydney, Australia

Project Perforated Canopy

Project Type Architectural & Facade Modeling

Project Commenced April 2019

Software Used Revit 19’, AutoCAD 19’ , Navisworks 19’

What were the key Outcomes?

- Roof Sheet modelling was done as per LOD 300 standards and a detailed clash report was presented along with design to the Architect. Clash-free designs of LOD 350 were created including upgraded designs that were proposed by us in the clash reports.

- Generated shop drawings incorporating complete fabrication and installation of all components, to be utilized by specific trade contractors and fabricators.

- Building elements are modeled as specific assemblies with complete fabrication, compilation, installation and detailed reports in addition to precise quantity, size, shape, location, and orientation.

- The delivery of all 75 drawings was completed in fast tracked weeks.

- Created bid-ready BIM models with accurate modeling and shop drawings to aid detailed estimation. Produced a graphical representation of model elements and details as a specific system, demonstrating their assembly in terms of size, shape, orientation and their interface with other elements of the building.

- The delivered documentation also included graphical depiction with non-graphical (written) definitions.

- Using BIM methodology, we were able to establish improved collaboration between teams.

CHALLENGES

- Complex profile & Sheet Laying

- The sloped sheet roof of the building was challenging the rest of the building design.

- Our strategic predictions showed that it would be highly complex while constructing the rooms and façade especially installation of Light Fixtures.

- It was also a hefty task for laying out the sheets.

- The other main challenge was short delivery time for which the project was fast tracked.

KEY LEARNINGS

- Client was able to save time and money through effective construction practices.

- Quick and effective response to cater the client needs.

- Allocation of expert Architectural domain team.

- CDE Model implementation where all stakeholders exchange project information

- Quality Check on each output that is delivered to the client.

KEY TAKE-AWAY

It is important to understand current work processes and practices Look to implement quick wins to leverage buy-in from employees. Do not try and change everything at once. Put metrics in place to measure success of implementation